-

CLIENT

Protechnic

-

SECTOR

Manufacturing

-

TECHNOLOGY

Solar PV

-

SYSTEM SIZE

195 kWp

-

PV MODULES

Q Cells

-

NO. OF MODULES

601

-

ESTIMATED ANNUAL OUTPUT

186,095 kWh

-

ANNUAL CO2 SAVINGS

111,657 kg

Client

Protechnic Ltd is a UK based manufacturing company. Operating from their factory in Nailsea, Bristol – the organisation has been designing and manufacturing cases and protective foam inserts to supply British industry for over 25 years.

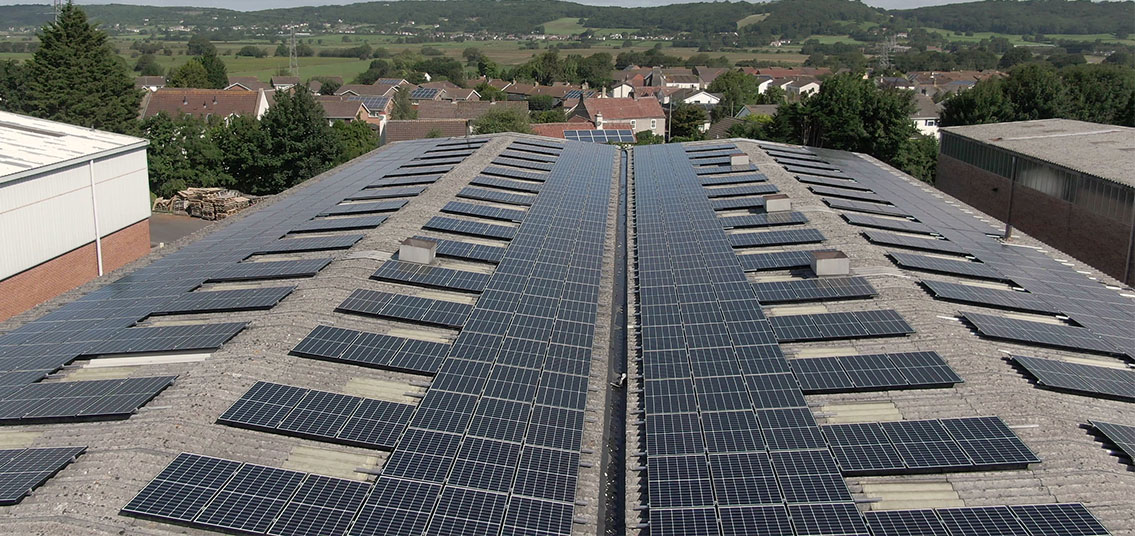

Protechnic has installed a solar panel system across their entire factory roof, dramatically cutting their carbon footprint. Along with installing a new top of the range solar power system, Protechnic has also replaced 80% of their factory lighting with LED lights. These lights are designed to assist with energy consumption and reduction of Protechnic’s carbon footprint.

The team at Protechnic are continually looking for new ways to reduce the impact on the environment caused by the factory and manufacturing facility. Over the coming months, they will be working to continue these developments by increasing the use of recyclable materials and reducing the use of harmful substances and adhesives used in the manufacturing process.

TASK

As part of phase one, Solarsense installed a 49.4kWp flat roof solar panel system on the factory roof in Nailsea. The grid-connected PV array was mounted to the roof using a ballasted base frame, containing 152 solar panels. The system generated in excess of 45,809kWh of clean electricity per year, whilst mitigating 17.5 tonnes of carbon emissions per annum. This initial system was designed to payback all installation costs within 4 years and will continue to generate a profit for the business for more than two decades.

Following the success of their first solar panel installation, Protechnic then returned to install a further 449 solar panels to increase their financial and carbon savings.

The total 195kWp commercial solar PV system now generates more than 186,095kWh of electricity per year. This energy is either used to power their manufacturing plant or fed back to the National Grid; reducing the organisations’ carbon emissions by more than 111,657kg per year. As well as improving the company’s carbon footprint, the large-scale solar panel system has significantly reduced the company’s energy bill, saving approximately a quarter of their current energy costs.

Services provided

- Detailed technical design (solar PV & EV charge points)

- Full supply, installation & commissioning

- Full handover including MCS registration and G99 grid connection

Video